AUTOMATED NTC SENSOR ASSEMBLY

Robotlyne is a trusted provider of automated NTC sensor assembly solutions, backed by 20 plus years of hands on experience in the NTC sensor industry.

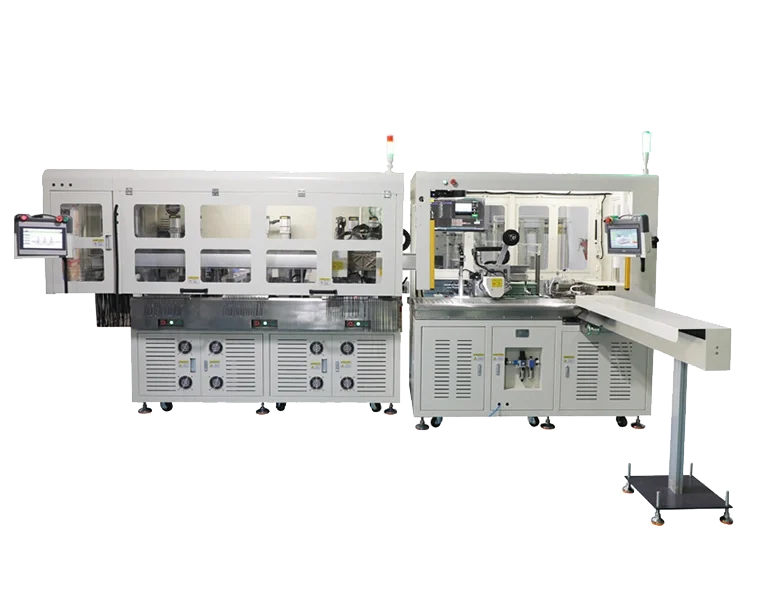

NTC Sensor Assembly Example

We understand the assembly processes, quality requirements, and validation standards across a wide range of applications, and we design automation systems that match your product design, materials, and throughput goals.

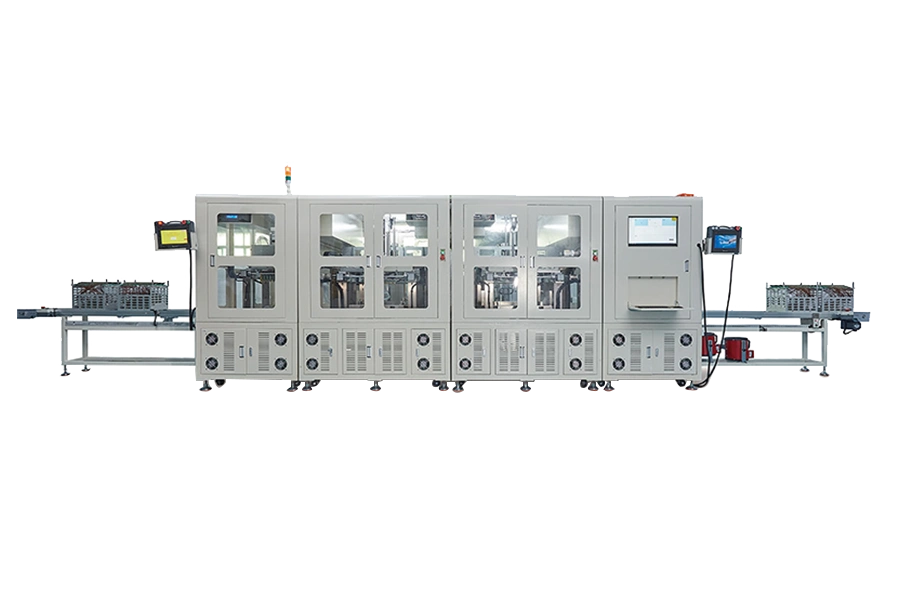

Modular Assembly Workstations

Robotlyne’s modular design approach allows each workstation to run as a standalone unit or operate in sync as part of an integrated line. Manufacturers can start with a single custom automation station to meet immediate needs, then expand and upgrade over time into a complete automated production line.

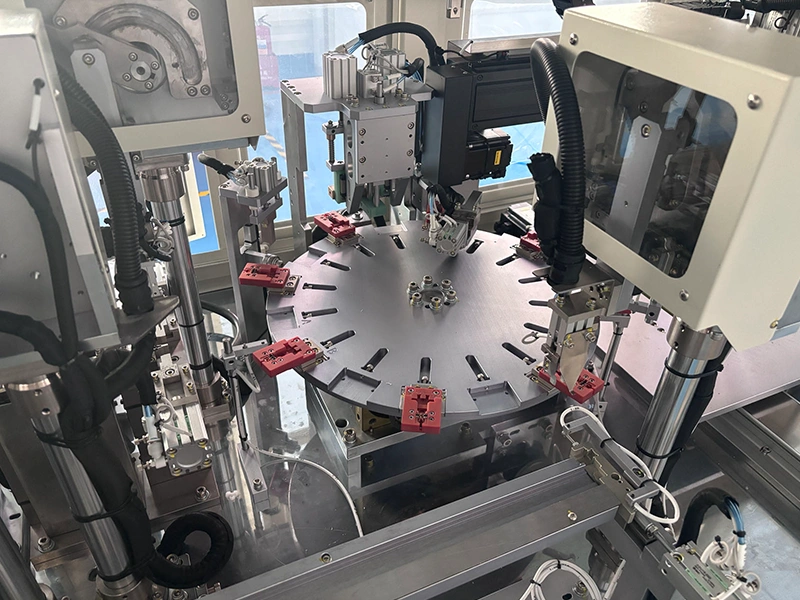

Wire Feeding, Wire Cutting, Wire Stripping, Wire Twisting, Flux Dipping, Solder Dipping, Tape Application, and Terminal Crimping

Feeding, Straightening, Forming, Lead Cutting, Wire Joining, and Soldering

Industry Experience Includes

We understand each sector’s NTC sensor assembly requirements, from quality specs to traceability, and design automation to match.

Consumer Electronics

Home Appliances

Automotive

Automation Projects We’ve Delivered

Precision Automated Assembly Line for NTC Sensors

Streamline NTC assembly with 2,000 PCS/H automated lines. 99.7% yield and $30k monthly savings through integrated wire processing, soldering, and proprietary software.

Read moreAutomated Temperature Sensor Dip Coating and Encapsulation System

Custom automated temperature sensor encapsulation system with uniform adhesive coating, bubble reduction, and output up to 11,000 parts per hour.

Read moreWe Are Honored to Serve These Companies

Interested in our solutions?

- Contact our experts to learn more about Robotlyne’s NTC sensor assembly solutions.

- See if your project is feasible fast. Get a clear scope, timeline, and Free ROI Analysis.